Get To Know “Vibration”

Vibration is a mechanical phenomenon whereby oscillations occur about an equilibrium point.

In many cases, vibration may adversely affect the durability and reliability of products and cause problems such as structural damage, functional failure, abnormal stopping and other unexpected disasters.

Vibration test is an effective countermeasure to prevent these problems by simulating the vibration environment to which the product will be subjected during transportation, installation and practical use so as to determine the resistant ability of products under vibration environment. It helps to detect design weakness, verify the integrity and identify the durability.

Basic principle

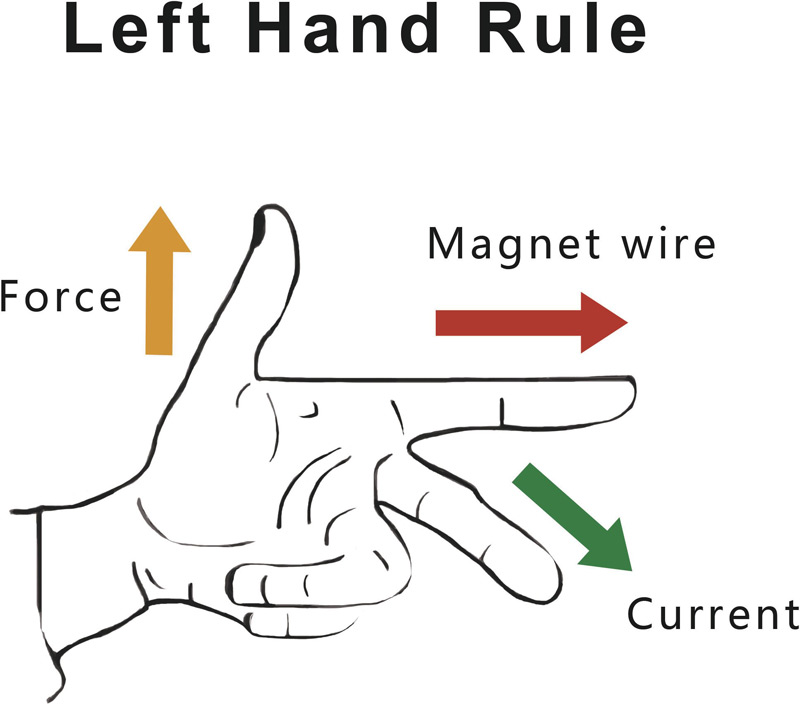

Electro-dynamic vibration shaker is a device that can convert electrical energy into mechanical energy, the basic working principle of which is based on Ampere’s law where current-carrying conductors are subjected to electromagnetic forces in a magnetic field.

The subjected electromagnetic force of current-carrying conductor is proportional to the current in the conductor, the effective length of the conductor in the magnetic field, and the magnetic induction density of the magnetic field where the conductor is located. That is, F=BLI. The direction of electromagnetic force is determined by the left-hand rule.

F:Force (N)

B:Magnetic induction

density of the magnetic field (T)

I:Current in the conductor (A)

L:Effective length of conductor (m)

Working principle

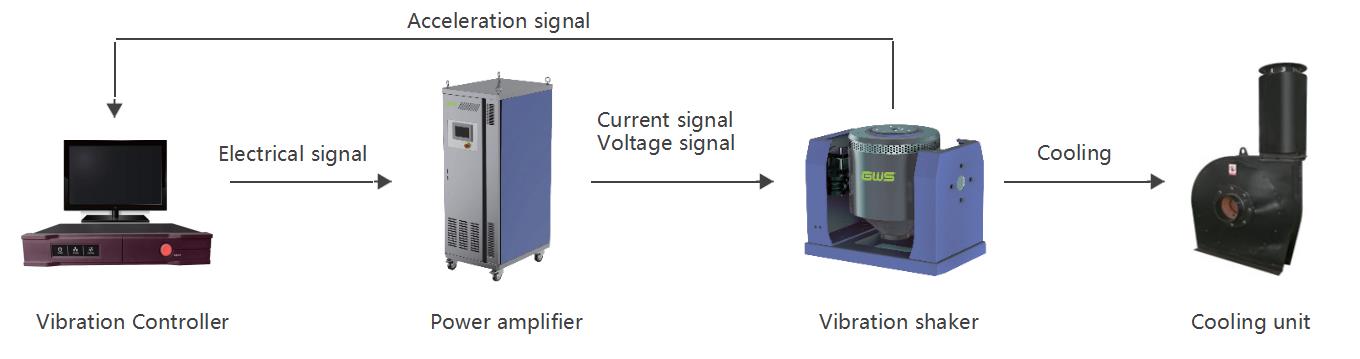

Electro-dynamic vibration test system is a typical closed loop control system composed of vibration shaker, power amplifier, vibration controller, cooling unit and measurement instrument (e.g.: accelerometer), etc.

Vibration or shock motion is generated by the shaker in response to an amplified drive signal that originates at the controller. The accelerometer will provide the collected signal to the controller for real-time correction, and send back to the power amplifier. Choose proper cooling method (air-cooled or water-cooled) to ensure good heat dissipation.